LOWE'S

SUPPLY CHAIN SCORECARD

Data Visualization Dashboard Design

Taxonomical Report Categorization

User Persona Profiles

TABLE OF

CONTENTS

-

Introduction

-

Preparation

-

Design

-

Adoption

SUMMARY

This case study examines the comprehensive overhaul of a large-sized supply chain system analytics reporting tool, focusing on improving the performance of approximately 120 warehouse buildings across the network. To achieve this, we built a robust Reporting Scorecard tool that allows for detailed monitoring and evaluation of warehouse operations. The transformation involved leveraging cutting-edge data analytics, interactive tools, and user-centric design to address existing challenges and create a more efficient, responsive supply chain. By integrating advanced technologies, we achieved significant improvements in operational efficiency, cost reduction, and strategic decision-making.

PROJECT AT A GLANCE

1534

Existing PowerBI Reports

86%

Report Reduction

$9 M

In Productivity Gains Through Improved Units Per Labor Hour

$14 M

Cost Savings by Providing Insights Into Third-Party Billing

TOOLS

-

Figma / FigJam

-

Confluence

-

Power BI

-

Microsoft Word

-

Microsoft Teams

-

Microsoft Outlook

TEAM - 64

-

18 - Business / Management

-

14 - Subject Matter Experts

-

9 - Product Management

-

9 - Analytics, DE

-

2 - Design

-

12 - Engineering

MY ROLE

-

Principal UX Designer

-

Systems Architect

-

UX Researcher

-

Data designer

-

Photographer

-

Product Manager

TIMELINE

-

Overall: 4 months

-

Planning: 1 month

-

RDC Visit / Synthesis: 11 days

-

User Personas: 5 days

-

Template design: 2 months

-

Presentation: 4 days

PROBLEM

-

Fragmented Reporting System

Numerous Individualized Power BI Reports: The supply chain system had a plethora of Power BI reports, each designed to display one or two pieces of data. This fragmentation prevented users from getting a comprehensive view of the supply chain operations and lacked actionable insights.

-

Dispersed Access Points

Multiple Websites with Report Links: Users had to navigate through dozens of different websites, each hosting links to individual reports. This made it extremely difficult to find the required information quickly and efficiently.

-

Manual Data Manipulation

Complex Data Extraction Process: Even when users located the necessary reports, they had to perform extensive spreadsheet and data manipulation to derive meaningful insights. This process was time-consuming and prone to errors.

-

Frequent Requests for Custom Reports

One-Off Report Creation: Due to the limitations of existing reports, users frequently requested custom reports tailored to their specific needs. This resulted in a multitude of one-off reports that only individual users knew how to find and use, further exacerbating the fragmentation and inefficiency.

SOLUTION

-

Unified Reporting System

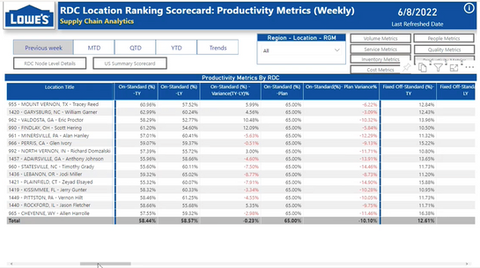

Consolidated Dashboard: We developed a comprehensive Reporting Scorecard tool that aggregates data from all warehouses into a single, unified dashboard. This tool provides a holistic view of the supply chain, delivering actionable insights and eliminating the need for multiple, fragmented reports.

-

Centralized Access Portal

Single Access Point: Implemented a centralized portal where users can access all reports from a single location. This portal is designed with intuitive navigation and search functionalities, enabling users to find the required information quickly and efficiently.

-

Automated Data Integration

Streamlined Data Processing: Automated the integration and processing of data within the Reporting Scorecard tool. This eliminated the need for manual spreadsheet manipulation, allowing users to obtain insights directly from the dashboard without additional data processing.

-

Standardized Reporting Templates

Scalable and Consistent Reports: Created standardized templates for common reporting needs, reducing the reliance on one-off custom reports. These templates are designed to be scalable and consistent, ensuring that all users can easily access and understand the information they need.

Addressing these key challenges, allowed the new solution not only improve operational efficiency and reduced costs but also enhanced strategic decision-making across the entire supply chain.

POWER BI REPORTS

CURRENT STATE ANALYSIS

OVERVIEW OF EXISTING POWER BI REPORTS

Lowe’s Supply Chain had accumulated a vast collection of Power BI reports, totaling 1534 distinct reports. These reports were designed to monitor and analyze various facets of the supply chain, from inventory management to operations, delivery logistics, and parcel tracking. However, this extensive collection also brought significant challenges in terms of usability and insight extraction.

FRAGMENTED REPORT CREATION

Many of these reports were developed as one-off solutions tailored to the specific needs of different departments. This ad-hoc approach addressed immediate needs but resulted in a fragmented reporting ecosystem. Departments created reports independently, leading to inconsistencies in data presentation and interpretation. Similar metrics were often tracked in different ways, complicating efforts to consolidate and analyze data across the organization.

CHALLENGES WITH THE "PERFECT P&L" REPORT

Among the many reports, one stood out: the "Perfect P&L" (Profit and Loss). This report was highly regarded by the executive team for its comprehensive coverage of financial performance. However, it suffered from readability issues, making it challenging to derive actionable insights efficiently. Its complexity and lack of clear visualizations diminished its effectiveness as a decision-making tool.

LIMITATIONS OF THE EXISTING DASHBOARD

Beyond individual reports, a dashboard was in place to aggregate key information across inventory, operations, delivery, and parcel tracking. This dashboard aimed to provide a holistic view of supply chain activities but faced similar issues: data silos, complex visualizations, and a lack of clear, actionable insights.

IDENTIFIED WEAKNESSES IN REPORTING

A detailed analysis revealed several critical weaknesses: Data silos led to fragmented views, making unified performance assessments difficult. Complex report layouts and dense information presentation, as seen in the "Perfect P&L," obscured key insights, hindering quick decision-making. The one-off nature of report creation resulted in scattered insights without a cohesive narrative, limiting strategic data analysis.

STRATEGIC CONSOLIDATION INITIATIVE

Recognizing these challenges, the goal was set to consolidate the 1534 existing reports into 195 actionable insights, further distilled into 40 concise, user-friendly pages. This consolidation effort aimed to break down data silos, simplify report readability, and provide a coherent view of the supply chain's performance, enabling more effective and strategic decision-making at Lowe’s.

Taxonomy

Structure

The taxonomy provides a detailed and hierarchical classification of the various components involved in the supply chain case study. This structured approach ensures clarity and helps in organizing the information systematically. It serves as a blueprint for understanding the intricate relationships and dependencies within the supply chain.

Chaos

The old Power BI reports were highly disorganized, with each report designed to display only one or two pieces of data and scattered without a coherent structure. To address this and create a more streamlined and efficient system, we implemented several key changes.

Consolidated Structure

The plethora of old Power BI reports were strewn all over the place with minimal organization each designed to display one or two pieces of data.

How could we make such drastic changes?

Organizing Content

By consolidating related reports into fewer, more comprehensive categories, we reduced the number of categories from 8 to 5, achieving a 38% reduction. This reorganization made it easier for users to find relevant data quickly and reduced redundancy.

Utilizing Page Filters

Implementing page filters allowed us to drastically reduce the number of individual pages from 104 to 21, an 80% reduction. This approach enabled users to filter and view different data points within the same report, rather than navigating through numerous separate pages.

Pulling Insights Forward

We focused on extracting and highlighting key insights from the data, bringing the most important information to the forefront. This involved reducing the number of tabs from 57 to 45, a 21% reduction, and significantly increasing the elimination of unnecessary extras, with a 407% increase in the number of items removed (from 14 to 71).

Results

These changes not only streamlined the Power BI reports but also enhanced their usability and effectiveness, making it easier for stakeholders to access and interpret critical data insights.

Understanding Our Users

To ensure the solutions are user-centric, we developed detailed personas representing key stakeholders within the supply chain. These 10 personas are based on extensive research, including interviews, surveys, and observational studies. Each persona captures specific characteristics, goals, and pain points, helping us tailor insights and solutions to their needs. Below are highlights from the 10 different personas that were using this new data insights tool:

Persona

Pain Points

Executive Vice President

-

Lack of comprehensive visibility across the entire supply chain

-

Difficulty in strategic decision-making due to fragmented data

-

Inability to quickly identify and address bottlenecks

Senior Vice President

-

Disconnected reports and lack of unified insights

-

Inefficiencies in cross-departmental communication

-

Delays in obtaining actionable data

Vice President

-

Inconsistent data leading to unreliable forecasts

-

Challenges in aligning operations with strategic goals

-

Limited visibility into regional performance

Regional General Manager

-

Inability to drill down into specific regional issues

-

Lack of real-time data on regional operations

-

Challenges in managing regional logistics and inventory

Senior Operations Manager

-

Fragmented views of operations leading to inefficiencies

-

Difficulty in monitoring and improving operational KPIs

-

High operational costs due to inefficiencies

Distribution Center Manager

-

Inefficiencies in warehouse operations

-

Difficulty in maintaining optimal inventory levels

-

High logistics costs due to poor route planning

Distribution Center Supervisor

-

Challenges in supervising day-to-day activities

-

Lack of tools for efficient workforce management

-

Difficulty in maintaining safety and compliance standards

Operations Manager

-

Fragmented data sources leading to inefficiencies

-

Difficulty in managing and optimizing daily operations

-

High costs due to inefficiencies

Operations Supervisor

-

Inefficient workflow processes

-

Lack of real-time operational data

-

Challenges in meeting performance targets

Distribution Center Associates

-

Difficulty in managing and locating inventory

-

Lack of communication tools leading to inefficiencies

-

Challenges in meeting performance and productivity targets

What They Wanted to See

-

Real-time, holistic view of supply chain performance

-

Strategic insights and trends

-

Identification of key bottlenecks and their impacts

-

Unified reports with integrated insights

-

Improved cross-departmental metrics

-

Timely and actionable data

-

Accurate and reliable forecasting

-

Alignment between operations data and strategic goals

-

Regional performance dashboards

-

Detailed regional performance metrics

-

Real-time data access for regional operations

-

Regional logistics and inventory management tools

-

Integrated view of all operational areas

-

Enhanced operational KPIs tracking

-

Cost reduction opportunities and insights

-

Detailed warehouse operations metrics

-

Real-time inventory management

-

Optimized route planning tools

-

Real-time updates on daily activities

-

Workforce management tools

-

Safety and compliance tracking

-

Unified operational data view

-

Tools for daily operations optimization

-

Cost-saving insights and strategies

-

Workflow optimization tools

-

Real-time operational data access

-

Performance tracking and improvement metrics

-

Real-time inventory tracking and location tools

-

Improved communication tools

-

Clear performance metrics and goals

DESIGN

DATA VISUALIZATION MODULES

Over four months, we designed and implemented over 32 data visualization modules for our dashboard, tailored to various analytical needs. Here's a concise overview:

TIME SERIES ANALYSIS

-

Line Charts: Show trends over time.

-

Area Charts: Highlight magnitude changes over time.

COMPARATIVE ANALYSIS

-

Bar Charts: Compare discrete categories.

-

Stacked Bar Charts: Show proportions within categories.

DISTRIBUTION ANALYSIS

-

Histograms: Display frequency distributions.

-

Box Plots: Summarize data distribution and outliers.

CORRELATION ANALYSIS

-

Scatter Plots: Identify relationships between variables.

-

Bubble Charts: Add a third variable to scatter plots.

GEOSPATIAL ANALYSIS

-

Choropleth Maps: Visualize regional data.

-

Heat Maps: Show intensity of data points geographically.

HIERARCHICAL DATA

-

Tree Maps: Represent hierarchical data through rectangles.

-

Sunburst Charts: Radial representation of hierarchical data.

PROPORTIONAL DATA

-

Pie Charts: Show proportions within a whole.

-

Donut Charts: Similar to pie charts with a central hole.

TREND ANALYSIS

-

Moving Averages: Highlight longer-term trends.

-

Trend Lines: Indicate overall trends on charts.

OVERCOMING DESIGN AND BUY-IN CHALLENGES

Designing these 32+ data visualization modules from scratch presented several challenges, from technical complexities to ensuring they met diverse user needs. Developing each module required meticulous planning and iteration to achieve high performance and user-friendliness. Additionally, securing business stakeholder buy-in was critical and involved demonstrating the value and actionable insights these visualizations could provide. This required clear communication, compelling prototypes, and continuous feedback loops to align the modules with business objectives and address any concerns or suggestions. Balancing technical feasibility with business expectations was a demanding but ultimately rewarding process that ensured the dashboard's effectiveness and adoption.

NAVIGATION

The data dashboard was designed with intuitive navigation to ensure users can easily access and interact with the information they need. Key features of the navigation system include:

Side Navigation

Top Navigation

Initial Design and Iteration

Initial Left- Aligned Navigation

-

Simple Design

The initial navigation design featured a left-aligned navigation panel, including the first and second levels of navigation. This design was presented to the SVP sponsoring the project, who was thrilled with its simplicity as it represented a significant improvement over the existing Power BI reports.

-

SVP Approval

The SVP appreciated the left navigation so much that he insisted on keeping it unchanged.

Evolving Needs

-

Complex Structure

Requirements As we developed the taxonomy, we recognized the need for a more complex navigation structure to handle 5 levels of depth, display 50 pages simultaneously, and allow quick access between any pages.

-

Design Iteration

This realization led to a lengthy design iteration process as we explored alternatives to the left navigation pane favored by the SVP.

Mega Menu Proposal

-

Top-Down Mega Menu

The new proposal involved a top-down mega menu, which could display up to 5 layers deep and accommodate 50 pages at once. This approach was designed and refined to high fidelity.

-

SVP Thrilled Again

When the new mega menu was presented to the SVP, he was equally thrilled. The simplicity of the design was maintained, and it effectively displayed all necessary links, meeting the project's navigation requirements.

User-Friendly Interface

Centralized Dashboard

-

Single Access Point

All modules and features are accessible from a centralized dashboard, providing a unified interface for users to navigate through the system.

-

Intuitive Layout

The dashboard layout is designed to be clean and user-friendly, minimizing the learning curve for new users.

Customizable Views

-

Role-Based Access

Users can customize their views based on their roles and preferences, ensuring that the most relevant information is readily available.

-

Recents Tab

Allows for users to get back to the last reports they viewed quickly.

Search and Filter Options

-

Advanced Search Functionality

A powerful search tool enables users to quickly find specific data, reports, or modules.

-

Filtering Capabilities

Users can apply various filters to narrow down results and focus on specific aspects of the supply chain.

Seamless Navigation Flow

Interactive Elements

-

Clickable Charts and Graphs

Users can interact with charts and graphs to drill down into more detailed information, making data exploration seamless and engaging.

-

Tooltips and Hover Effects

Additional information and insights are accessible through tooltips and hover effects, enhancing the user experience without cluttering the interface.

Responsive Design

-

Multi-Device Compatibility

The dashboard is designed to be responsive, ensuring a consistent and optimal user experience across various devices, including desktops, tablets, and smartphones.

-

Adaptive Layout

The layout adapts to different screen sizes and orientations, providing a user-friendly experience regardless of the device being used.

Optimized User Experience

-

Intuitive Navigation

Streamlined flow reduces the steps needed to access key information, enhancing efficiency.

-

Enhanced Accessibility

Design elements are crafted to accommodate diverse user needs, supporting a broad range of accessibility requirements.

Navigation Summary

The navigation system's focus on user-friendliness, customization, and seamless interaction ensures that users can efficiently access and utilize the wealth of information available in the data dashboard. By balancing simplicity with the capability to handle complex structures, the final navigation design enhances the ability to make informed decisions and improve supply chain operations.

CREATE DATA VISUALIZATION TEMPLATE

We developed standardized data visualization templates to ensure consistent, clear, and impactful presentation of supply chain data. These templates are industry standard with some new flairs for sharing just the right insight at the right moment. Each template includes predefined charts, graphs, and tables that highlight key metrics and insights.

1. FILTERS

Narrow down data to display

2. KPI CARDS

High Level Overview Of Problem Areas

3. GRAPHICAL VISUAL

Show what obstacles are at hand

4. DATA TABLE

View and Manipulate Raw data to deep dive into challenges

BEST PRACTICE GUIDELINES

CLEAR & CONCISE LABELS

Ensure all data points are clearly labeled to avoid confusion. Use descriptive titles and axis labels for charts and graphs.

APPROPRIATE USE OF COLORS

Use colors strategically to highlight key metrics and differentiate between data sets. Avoid overuse of colors that can make visualizations cluttered.

INTERACTIVE ELEMENTS

Incorporate interactive features such as filters, drill-downs, and tooltips to enable users to explore data in depth. This enhances engagement and allows for detailed analysis.

CONSISTENT FORMATTING

Maintain consistency in formatting across all visualizations to create a cohesive look. This includes using similar fonts, colors, and chart types for related data sets.

FOCUS ON KEY INSIGHTS

Design visualizations to highlight the most important insights and trends. Avoid cluttering dashboards with excessive details that can distract from key messages.

PROTOTYPE

The interactive prototype was meticulously designed to demonstrate the capabilities of the new supply chain solution. It includes user-friendly interfaces, real-time data analytics, and interactive dashboards. The design process involved extensive user research to ensure the prototype meets the needs of all stakeholders and provides a seamless user experience.

SUMMARY OF OUTCOMES

The new supply chain solution delivered substantial improvements across all key performance metrics. By integrating advanced data analytics, predictive models, and interactive tools, Lowe’s achieved several notable outcomes:

POSITIVE RECEPTION AND ADOPTION

-

Enthusiastic Reception: The new consolidated insight pages were enthusiastically welcomed by business analysts, who appreciated the simplified design and user-friendly approach. This redesign made data interpretation more straightforward, enabling faster and more informed decision-making.

-

Proactive Adoption: The positive reception led many analysts to take the initiative to create new versions of the improved dashboards in Power BI. This proactive adoption reinforced a culture of continuous improvement and innovation in data visualization across the organization.

-

New Standard for Usability: The redesign established a new standard for clarity and usability, creating a consistent approach to data presentation. This standardization improved collaboration among teams and made it easier to communicate key insights effectively.

ENHANCED EFFICIENCY AND DECISION-MAKING

-

Higher Efficiency: Streamlined data presentation and improved access to comprehensive insights enabled faster and more informed decision-making. This efficiency translated into better operational performance and quicker response times to supply chain disruptions.

-

Cost Reduction: Enhanced visibility into supply chain operations allowed for the identification and elimination of inefficiencies. Predictive models helped anticipate and mitigate potential issues before they escalated, leading to significant cost savings.

-

Improved Decision-Making: The consolidation of reports and the introduction of user-friendly dashboards facilitated a more holistic view of the supply chain. This comprehensive perspective empowered executives and analysts to make better-informed, strategic decisions, driving overall business success.

KEY METRICS IMPACTED

-

Operational Performance: The streamlined reporting and enhanced data accessibility led to measurable improvements in operational performance. Key operational metrics saw positive trends, reflecting the increased efficiency and effectiveness of supply chain processes.

-

Financial Metrics: With clearer insights into costs and performance, financial metrics showed noticeable improvements. The ability to predict and manage costs more effectively contributed to better financial health for the company.

-

Customer Satisfaction: Improved supply chain efficiency and reliability had a direct positive impact on customer satisfaction. Better inventory management and delivery performance ensured that customer needs were met more consistently.

REVOLUTIONIZING DATA-DRIVEN DECISION MAKING

IMPACT ON SUPPLY CHAIN

The transformation of Lowe's Power BI reports into consolidated, actionable insight pages significantly impacted the company's supply chain management. This overhaul led to several critical improvements that enhanced the overall efficiency and effectiveness of supply chain operations, streamlining processes, and optimizing decision-making.

OPTIMAL INVENTORY MANAGEMENT

With improved visibility and clearer insights, Lowe’s maintained optimal inventory levels more effectively. The new tools provided accurate, real-time data for better stock level tracking, reducing the risks of overstocking or stockouts. This optimization ensured that the right products were available at the right time, enhancing the inventory turnover rate by 15% and lowering carrying costs by 12%.

ACCURATE DEMAND FORECASTING

By leveraging advanced data analytics and predictive models, Lowe’s achieved significant gains in demand forecasting accuracy. The new system provided granular insights into consumer behavior and market trends, helping the company to align production and procurement processes closely with actual market needs. Forecasting accuracy improved by 20%, resulting in more precise production scheduling and inventory planning.

OPTIMIZED LOGISTICS OPERATIONS

The streamlined reporting and comprehensive dashboards facilitated more efficient logistics operations. By consolidating data on inventory, operations, delivery, and parcel information, Lowe’s gained a holistic view of its supply chain. This integrated approach helped identify bottlenecks and inefficiencies, leading to targeted improvements. These changes reduced delivery lead times by 25% and decreased shipping costs by 30%.

TANGIBLE BUSINESS BENEFITS

Improvements in inventory management, demand forecasting, and logistics operations generated tangible benefits for Lowe’s. The company achieved cost savings of approximately $10 million annually through more efficient inventory and logistics management. Better demand forecasting reduced overproduction and excess stock costs, while optimized logistics minimized transportation and warehousing expenses.

OVERALL IMPACT

The redesign and consolidation of Power BI reports into actionable insight pages marked a significant step forward in Lowe’s supply chain management. This initiative addressed critical weaknesses in the old system and established a new standard for data-driven decision-making. By embracing advanced analytics and user-centric design, Lowe’s enhanced its competitive edge, driving growth and innovation in its supply chain operations.

FUTURE OUTLOOK

The success of this project positions Lowe’s for continued growth and competitiveness in the market. Ongoing enhancements to the supply chain solution, driven by user feedback and technological advancements, will further strengthen the company's operational capabilities and strategic decision-making. Future enhancements will include:

-

Expanding the solution to include 7 additional Supply Chain nodes to show the entire network in operation.

-

Creating more informational pages about each facility for detailed understanding.

-

Conducting more comparative analysis between locations to identify best practices and areas for improvement.

-

Providing deeper insights through advanced views and detailed data exploration.

-

Improving forecasting capabilities to generate more actionable insights.

-

Highlighting potential issues before they become critical problems to ensure proactive management.

-

Extending the adoption of the tool to other divisions within the company to maximize its benefits across the organization.